No products

Gate TITAN vs. Gate WARFET - Which is best for trigger response?

One question that is often asked when selecting a MOSFET installation is "which unit will provide the best trigger response for the gun?"

One question that is often asked when selecting a MOSFET installation is "which unit will provide the best trigger response for the gun?"

It is important to understand that trigger response is actually comprised of multiple factors, including the type of battery used, motor, gear ratio, wiring and more. Even the type of plug used on the gun influences this to a degree.

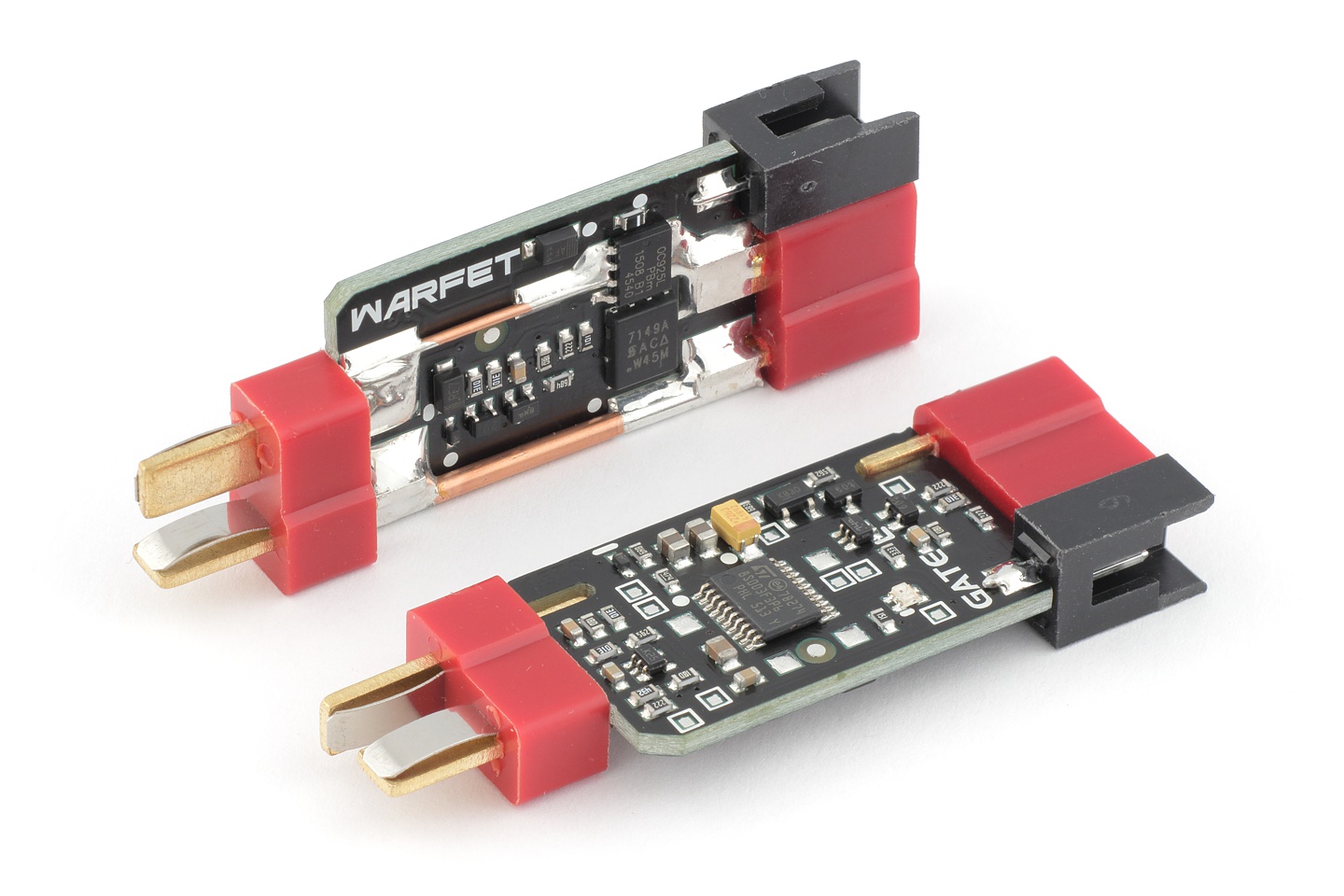

A MOSFET installation improves trigger response primarily through improving electrical efficiency. Most MOSFET installations will encompass a total-rewiring of the gun, in which case better and more efficient materials are used. Interruptions in the lines can be reduced or eliminated too. An inline MOSFET, such as the WARFET, will use a signal wire soldered to the trigger contacts as opposed to the power leads soldered on. The energy will be drawn from the battery directly to the motor, bypassing the mechanical trigger contacts entirely. By virtue of rerouting the power directly to the motor, the danger of trigger contact burnout or arcing is thereby eliminated. Incidentally, this is one of the major "selling points" of the inline-style MOSFET too.

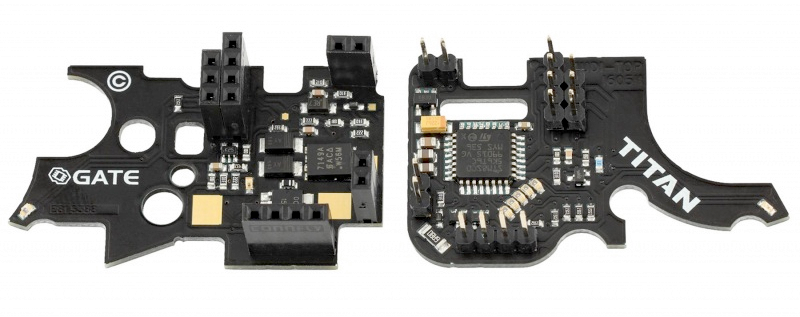

A Gate TITAN should be considered a MOSFET second and an Electronic Trigger Unit first. This is a drop-in unit that completely replaces the mechanical switch, as well as the cutoff lever components. The TITAN is essentially solid-state technology, using no mechanical aspects in its construction; it uses optical sensors to register trigger pulls and gear cycles. As the flagship product from Gate, the TITAN also boasts a wealth of features that can't be packed similarly into the WARFET or similar style MOSFET's. As the TITAN completely replaces the mechanical switch, it therefore completely eliminates any previous issues with trigger contact arcing. Additionally, since the cutoff lever is removed too, it is physically impossible for one to inadvertently "short-stroke" the trigger and cause a gearbox lockup as can be induced on a mechanical switch.

Both the WARFET and TITAN also offer optional pre-cocking functionality. Pre-Cocking mode will physically cock the piston in the full rearward position between shots. So on the next trigger pull, the piston simply has to be released to fire the BB as opposed to making a complete rearward and forward release cycle. It will roughly cut cycle time down by half, in effect.

So which is best for trigger response?

Bottom line, a WARFET will get you close to the TITAN in responsiveness, but it won't get you as light of a trigger pull, which is a major factor in the ability to rapidly operate the trigger.

On any inline MOSFET that is hardwired in, such as the WARFET, MERF, NanoASR, etc. you're still having to physically overcome two springs (trigger spring and trolley spring). There are also two additional springs and components that interact with the trolley (magazine cutoff and cutoff lever). Technically you can even consider the trigger contacts as a psuedo-fifth spring, as the trolley has to be pressed forward into them. These are angled in towards each other to ensure good connection with contact tab on the trolley, so it provides an additional point of felt resistance. All of these contribute to the heavier feel of the trigger on a mechanical setup.

On the TITAN, you eliminate all of this, including the cutoff levers, for just the trigger spring. If pairing it with the MAXX CNC tuneable trigger, which has a reduced strength trigger spring, you can obtain a very easy and relatively light trigger pull. Additionally, this trigger also allows you to set the amount of over-travel you want after the firing point. Lastly, the TITAN has adjustable trigger sensitivity, so the physical pull distance can be reduced to practically zero if so desired (it will in fact fire if you press sideways on the trigger at that point). All of this is why it's functionally easier to "flutter" the trigger on a TITAN equipped rifle as opposed to one that has an inline FET and the mechanical trigger contacts still. The TITAN and MAXX trigger should be considered as complimentary systems to one another.

On the TITAN, you eliminate all of this, including the cutoff levers, for just the trigger spring. If pairing it with the MAXX CNC tuneable trigger, which has a reduced strength trigger spring, you can obtain a very easy and relatively light trigger pull. Additionally, this trigger also allows you to set the amount of over-travel you want after the firing point. Lastly, the TITAN has adjustable trigger sensitivity, so the physical pull distance can be reduced to practically zero if so desired (it will in fact fire if you press sideways on the trigger at that point). All of this is why it's functionally easier to "flutter" the trigger on a TITAN equipped rifle as opposed to one that has an inline FET and the mechanical trigger contacts still. The TITAN and MAXX trigger should be considered as complimentary systems to one another.

For all intents and purposes, the TITAN system is practically the closest you can get to an HPA-like trigger on an AEG. If one takes two rifles with identical drive-train components, on semi-auto mode, the guy with the TITAN will likely be about to outrun the guy with the WARFET - with a lot less effort.

Additional Considerations

Aside from installation differences, the physical space taken up by the units varies too. The WARFET has to be housed outside and independent of the gearbox, thusly it will take up storage space that might otherwise be used by your battery. If you use a stock with hollow side tubes (PTS EPS, KWA OEM Crane style, etc.) then you can stick the WARFET beneath the buttplate and use the side tubes for nunchuck style batteries. Not all stocks have a hollow buttplate, however, so absence of such may preclude the option of using this particular MOSFET. It is not physically possible to situate the WARFET in the side tubes due to it being too wide to fit in those and complications with routing the wiring.

The Gate TITAN is contained entirely within the gearbox, therefore it does not impact battery space at all.

Special considerations for KWA AEG 2.5 and 3.0 rifles:

For KWA rifles with the AEG 2.5 and 3.0 gearbox shells with the last-round-cutoff feature, it is possible to convert the gearbox shell to the AEG 3.0+ version which is Gate TITAN compatible. However, opting for this upgrade means you do lose the last-round-cutoff capability. For users who wish to keep this cutoff functionality, the Gate WARFET is the recommended option if you want a full-featured MOSFET.

| MOSFET Comparisons | |

| Gate WARFET | Gate TITAN Advanced |

|

|