The Echo1 G36 series and by extension its clone(s) the JG, etc. has long been notoriously known for magazine feeding issues. Additionally, these are also plagued with equally notorious hop up chambers that are fragile and easily broken. Most of these issues stem from a poor air nozzle and hop up chamber design that doesn’t allow the nozzle to retract far enough to allow BB’s to feed into the hop up chamber. Due to this, a lot of Echo1 G36 owners like to upgrade their hop up chambers to more durable analogues. While a full metal CNC produced hop up chamber is certainly going to be more durable than the plastic one, it doesn’t always take care of the feeding issues.

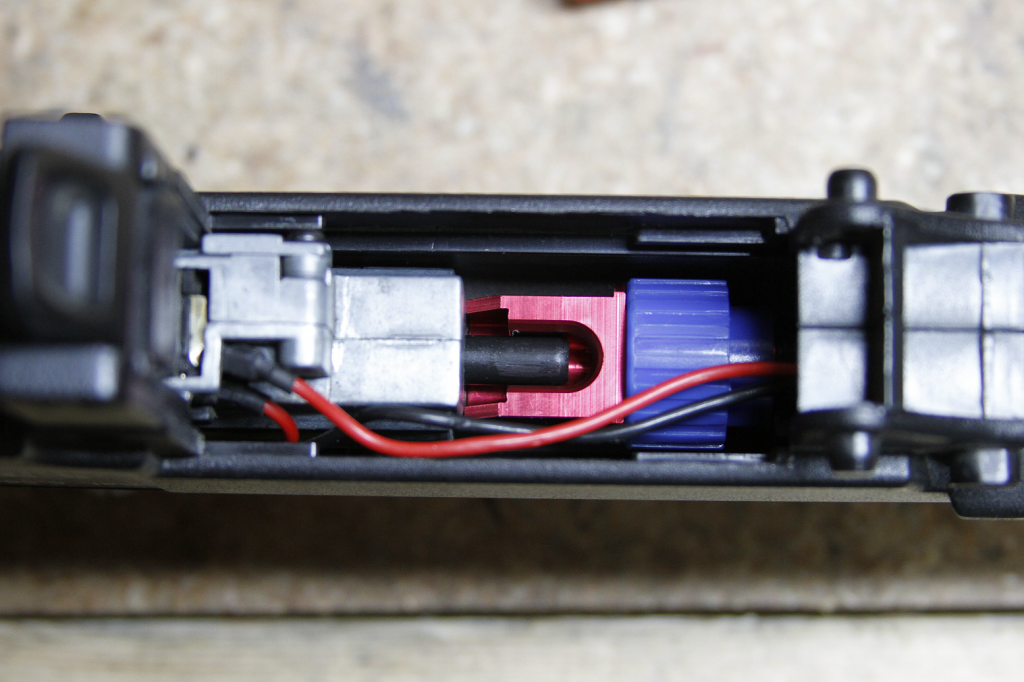

Here we have an excellent example of an Echo1 G36C with a CNC built hop up chamber that was presumably installed by the former owner. I am guessing this is a PPS brand or a clone based on the anodizing – but it is otherwise unmarked as to manufacturer.

The immediate thing I noticed was the air nozzle was not being allowed to complete a full forward cycle. This is due in part to two things:

The immediate thing I noticed was the air nozzle was not being allowed to complete a full forward cycle. This is due in part to two things:

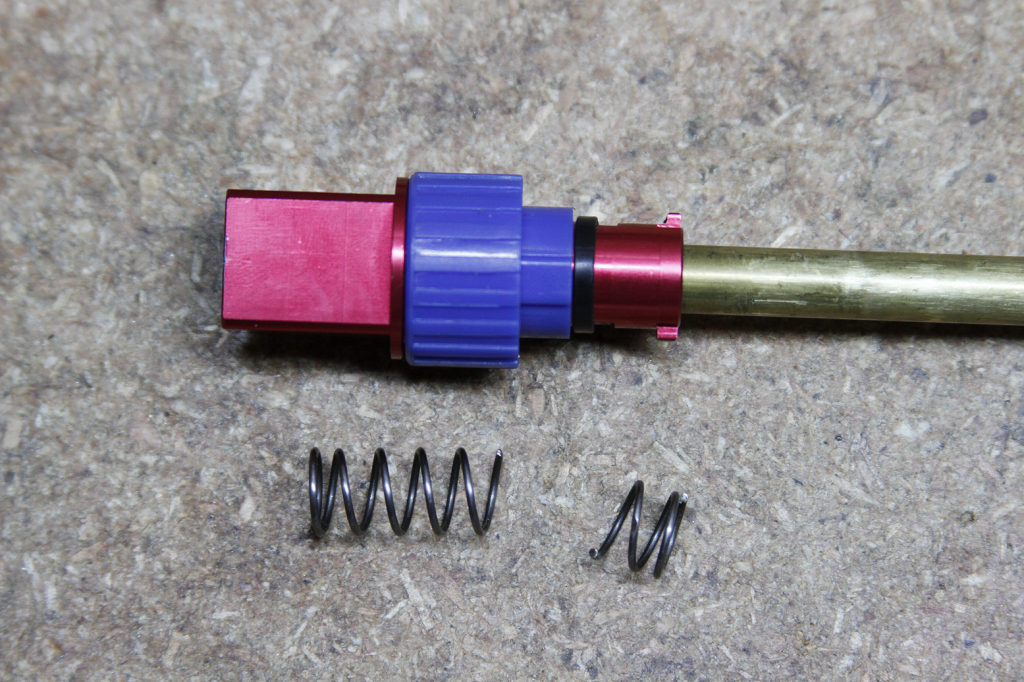

- The air nozzle has a “centering” spine on the top 12 o’clock position. If you’ve ever seen a KWA nozzle, they have these too.

- The hop up chamber is a lot thicker at the 12 o’clock position than the stock chamber. It also has a “step” inside of it, and this is exactly what the spline on the air nozzle was hanging up on.

It should also be noted that this particular hop up chamber was a lot tighter than the stock one, and this was putting undue pressure on the spline of the air nozzle and forcing it downward at a poor angle and further exacerbating the binding issue.

To solve this, the first thing to do is simply remove the spline from the air nozzle or find a replacement air nozzle of the same length that does not have a spline. Removing the spline can be accomplished by a razor blade or sandpaper. It is best to remove the spline entirely. In fact, I don’t really know why it’s been included in the first place. Much like the KWA nozzles, it’s a particularly useless piece of engineering that does little but cause problems for the most part. And much like the KWA versions, you can greatly improve your air-seal and compression by replacing the nozzle with a better one (especially one with an o-ring inside).

The other item to note is that the G36 comes with a very strong barrel spring. This spring is in fact a lot stronger than those that are typically equipped on M4’s or most any other AEG for that matter. This is basically applying a lot of rearward force to the hop up chamber and can sometimes even cause it to slip the barrel retaining clip during installation in extreme cases. I will often remove 2 – 3 coils or find a lighter substitute:

If none of this has solved the misfeeding problems yet, then another area to look at is how long the hop up chamber is. Again, nothing in airsoft is ever quite to the spec’s they should be. As was the case with this hop up chamber which measures out too short, it requires a little spacer at the rear of the chamber to push it forward and this in turn allows the nozzle to retract enough to allow the BB’s from the magazine to enter the chamber.

Normally you only have to shim the chamber with a piece of electrical tape. Maybe a couple of layers at most. I’ve seen some that require more than this. A piece of zip-tie super-glued to the rear works great in the extreme cases:

Be forewarned that doing too much of this shimming can cause very bad air-seal and result in massive FPS loss. It’s something that has to be tested on a case-by-case basis.

Obviously it goes without saying, that you should also take a close look at the hop up bucking and make sure it is correctly installed as well as check for any barrel obstructions. A bad installation can most certainly cause feeding issues too. As was also the case with this gun….

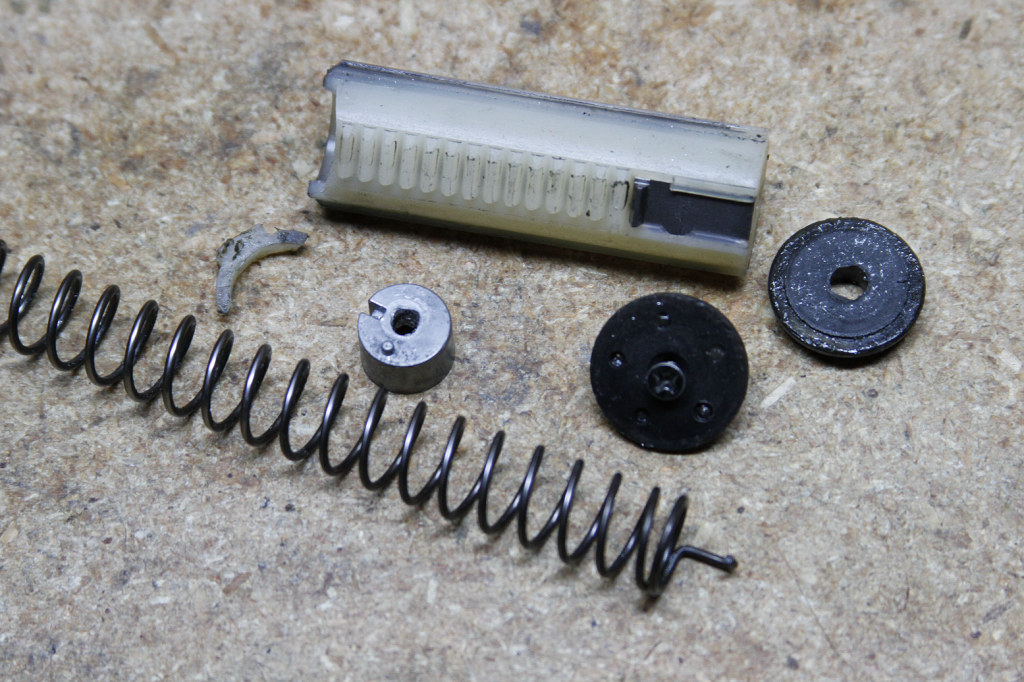

Generally though, I prefer to start with a known quantity when diagnosing feeding issues. And that means digging into the gearbox and examining the root source first. As fate would have it, here we have discovered a catastrophic failure of the piston, the piston head, and a completely vaporized o-ring. Actually, I never did find where the o-ring disappeared to in the end.

I’m not a fan of this style of spring and piston head attachment used by certain manufacturers, by the way. This is usually how their miserable lives end. Generally this is due to the screw coming loose over time due to recoil and then rounding out the retainer piece and then in turn this augers out the piston and from there it’s all downhill as all three systems collapse. A freely rotating spring on ball-bearings is always going to be a less stressful environment.

So as you can see, diagnosing the core problem can be one thing or it can be many things. In the case of this particular gun, it was a combination of many things that were all attributing to the problem. Sometimes there are quick and easy fixes, and sometimes you have to fix a lot of stuff. After all is said and done though, we now have a fully functioning and happy G36C.