VFC builds what is perhaps the best SCAR replica on the market. Externally they nearly match the real steel version 1 to 1. As an upgradeable platform, they make an excellent choice, as you won’t have to touch the externals at all, save for what you prefer to bolt on the plentiful rails. They have been known to have some internal issues, however, and we will be discussing these issues and how to diagnose them in this article.

VFC builds what is perhaps the best SCAR replica on the market. Externally they nearly match the real steel version 1 to 1. As an upgradeable platform, they make an excellent choice, as you won’t have to touch the externals at all, save for what you prefer to bolt on the plentiful rails. They have been known to have some internal issues, however, and we will be discussing these issues and how to diagnose them in this article.

The gearbox engine used in the VFC SCAR is a Version 2 design. It does use a few proprietary parts though, and it features an ambidextrous selector switch which can be problematic for some aftermarket purposes. For the most part, you will be well served by the stock internals. Depending on your goals and to get the best performance out of your SCAR, a few tweaks and upgrades will be necessary.

As always, clicking any of the pictures will bring up a larger view.

Shimming and Tappet Plate Interference

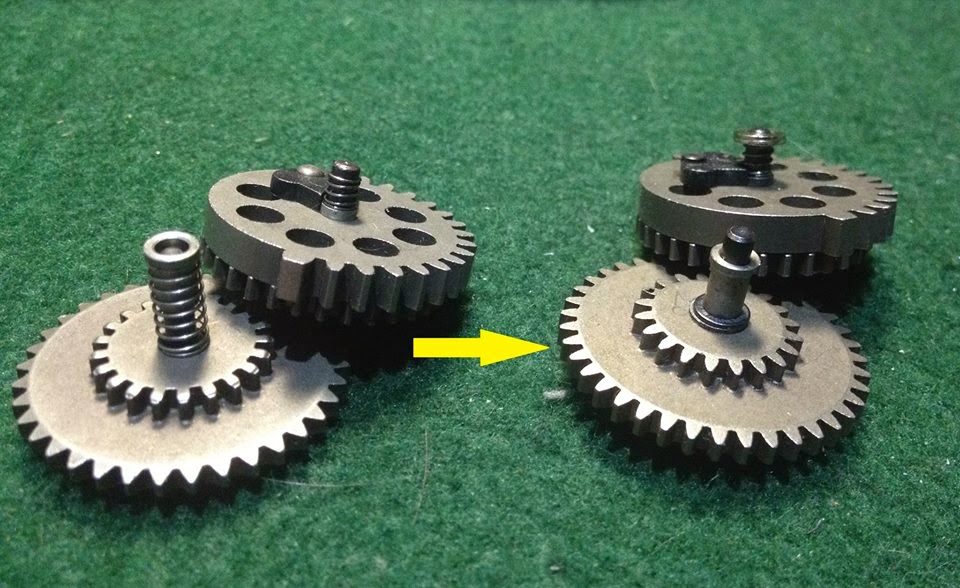

VFC uses self-shimming gearsets in their SCAR system. This is basically a conical spring that fits to either side of the gear and is supposed to keep things centered. In theory this works most of the time, but nothing is going to be as good or healthy for your gearbox as a true shimming job. The benefits of proper shimming are more precise gear alignment, quieter operation, and less margin-of-error (i.e. better lifespan.) If your gearset came with spacers, you can use those to help obtain proper shimming height. You may also use the sector gear spring as a 1.5mm spacer in compressed form.

Replacing the self-shimming parts may introduce issues with the tappet plate, however. Upon closer examination, you may see that the tappet plate now binds on the shim and / or the bearing surface. This can cause immediate issues with FPS loss as the tappet plate and air nozzle are not allowed to fully cycle forward and create a good air seal with the the hop up chamber:

|

|

|

|

|

|

|

|

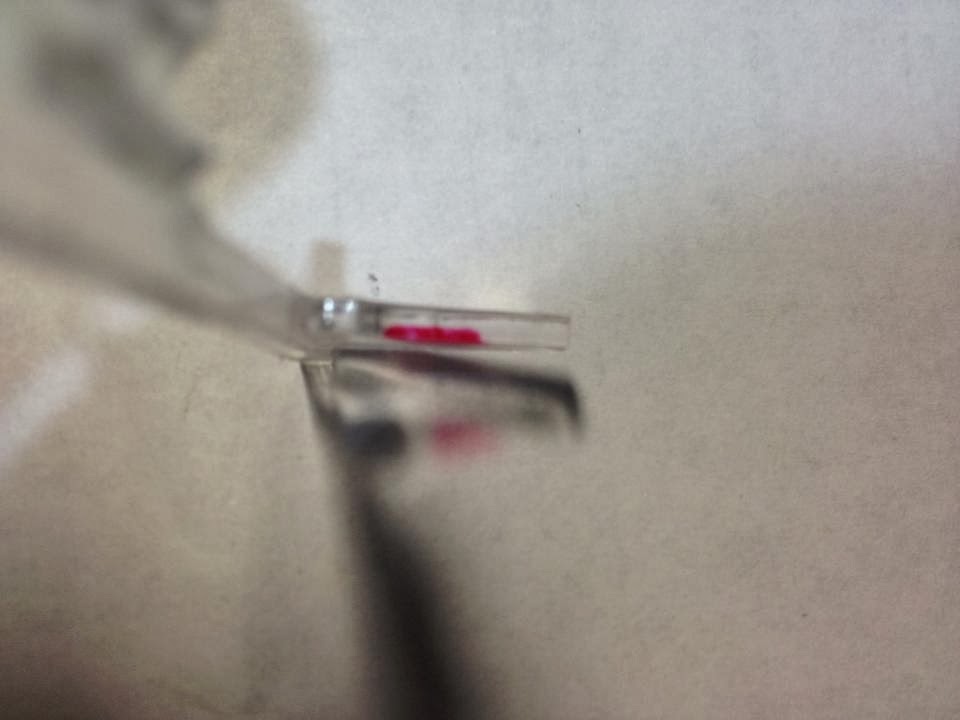

One remedial solution to the above problem is to file down the tappet plate to where it no longer binds on the shims. This is accomplished by thinning down the tappet plate:

In the case of this particular SCAR, thinning was necessary on the right side of the tappet plate. The red marked area is a rough approximation of material that may need to be removed in order to obtain proper clearance. Slow and steady is the key here. File a little, and check often.

Air Nozzle and Hop Up Chamber FPS Loss

If you need to replace your air nozzle due to damage or wear, it is vitally important you replace it with as close an example to the stock nozzle as possible. The stock VFC nozzle measures approximately 21.16mm in length. If you have too short of a nozzle you will likely run into the following issue:

If you need to replace your air nozzle due to damage or wear, it is vitally important you replace it with as close an example to the stock nozzle as possible. The stock VFC nozzle measures approximately 21.16mm in length. If you have too short of a nozzle you will likely run into the following issue:

That little gap you see between the air nozzle and the hop up bucking is responsible for a massive FPS loss in this particular example – it chronoed in at a pathetic 117 FPS. Not good at all.

Here you can also see the support/guide that rides just underneath the nozzle.

On a side note, it is recommended to discard the two set screws housed in the outer barrel – these can cause issues with the hop up chamber not seating back far enough and if cranked down too tight will actually crack and damage the hop up chamber. Obviously a cracked chamber can also result in lost FPS too.

Noisy Gearbox

This is probably the most common ailment to the VFC SCAR, and you will have doubtless read complaints elsewhere on the internet about the awful noise emanating from the gearbox. Besides proper shimming (which goes a long ways

towards quieting down this beast), the problem can be fixed by modifying the motor plate. The design of the VFC motor plate interferes and tends to lift the motor wires to cause height and angle problems. In some cases, this will cause such severe binding as to prevent the gearbox from cycling at all. It’s almost the same as an improperly adjusted motor height screw.

Here you can see the small modification done to the motor plate. This can be accomplished with the use of the ever-handy Dremel. After performing this modification, you should experience instant improvements with regard to noise, angle, and efficiency.

The motor plate seems to be a basic Version 2 design, so if you completely wreck it, it is an inexpensive replacement part found just about everywhere.

This is a general guide for tuning VFC gearboxes.

Pre-tuning

- Velocity check, rate of fire check.

Bushings:

- Original bushing removal.

- Bushing glue removal.

- Ball bearing install.

Shimming (molybdenum grease is highly recommended for gear lubrication):

- Grease cleaning.

- Gear teeth check.

- Bevel gear and motor gear match. Gear movement inside of gearbox should be no more than 0.2mm after gearbox is closed with screws.

- Remove spur gear spring, use proper shims to match bevel gear.

- Sector gear, shim between spring and bushing to match spur gear.

- Tappet plate movement check. File tappet plate if there is interference with sector gear shim (in the case of the SCAR)

- Close gearbox with all gears, piston, cylinder and tappet plate installed. Make sure it closes tightly without force.

- Rotate gears and check if piston can be pulled to the rear of gearbox smoothly

- Attach motor for gearbox test WITHOUT cylinder, tappet plate, piston, spring, and spring guide.

- Adjust motor height for best result of noise

- Check compression of piston, cylinder and air nozzle. VFC normally has an excellent air seal.

- Clean and lubricate if there is air leak. Use Silicon grease only for o-rings

Gears, Pistons, Springs, and other Parts

I don’t wholly consider it necessary to replace the stock gears in most AEG’s unless they’re truly awful. VFC gearboxes, for example, (including gears) are designed to be M150 ready, and have been tested with a 12 volt car battery at room temperature. My current setup is running a Guarder SP-110 spring, and is shooting at just under 400 FPS with .20g BB’s.

Out of personal preference, I have replaced the motor on my SCAR with a Tokyo Marui EG-1000. These motors are very durable, quite, and simply run and run and run. Not really a necessary swap, just personal preference.

Most internal parts are standard Version 2, and finding upgrades is relatively easy. Unfortunately, a few of the main components can be a lot harder if not impossible to upgrade. These parts are the ones made from clear polycarbonate and include: the piston, the tappet plate, selector switch plate, and the hop up chamber. With the exception of the hop up chamber (which is truly proprietary), you can find aftermarket parts that can be modified to fit if you’re patient and willing to spend the time and money searching. For the most part though, VFC spares are inexpensive and relatively easy to find and it isn’t really worth the expense to source parts that need modding.

Acknowledgements

Much of the technical information, VFC tune-up guide, troubleshooting tips and the internal gearbox photos contained herein are graciously provided by Sonic who has spent many tireless hours mastering the VFC. Without his help, much of this would still lie in the realm of mystery 😀